Which mandates drive sustainable practices? Which recent developments are creating the next wave of solutions that enhance the customer experience? What is the paradigm shift in purchase patterns? What are some of the notable partnerships?

Analyze how raw materials are mined for production, the push for sustainability, the evolution of consumer preferences, and more. Also, examine cutting-edge digital technologies shaping this landscape. Read the analysis to learn more.

Which robust technological advancements meet customer demands? What are the novel growth prospects for the pre-owned car sector? What are the impacts of HMI, ADAS, 5G, and EV on the PV industry? Explore the current industry size and segmentation.

An operation support system (OSS) is a vital component in ensuring smooth operations for connectivity service providers (CSPs). CSPs have traditionally relied on OSS solutions to manage their back-office operations of monitoring their network health and getting timely notifications in case of network faults and failures. Legacy OSS solutions can manage and monitor traditional physical network infrastructure; however, they are heavily dependent on manual interventions to fix network issues or reconfigure and redesign network elements to launch a new service. These OSS solutions also posed several other challenges, such as longer process cycles, increased security issues, and low data accuracy. The siloed architecture of a legacy OSS has often limited the capabilities of a CSP to innovate and launch new services to keep up with the growing demand from consumers and enterprises.

Schedule a dialog or email us at myfrost@frost.com to connect with an industry expert at no charge. We are taking unprecedented action to make our team available to help you cut through the media and politics to get factual one-to-one guidance for the issues and opportunities that matter most to your business.

How to boost agility and supply chain resilience to mitigate challenges

Analyze the new developments and their impacts on vehicle maintenance

Read more Request Info

Explore the revenue models to capitalize on charging operators

Read more Request Info

What are the operational strategies that focus on corporate structure?

Read more Request Info

How are SLM solutions helping with contract renewal negotiations?

Read more Request Info

Explore accurate and tailor-made experiences in the digital space

Read more Request Info

Explore disruptive technologies and their impact on future batteries

Read more Request Info

Leaders should pay attention to the potentially transformative role of machine learning in making engineering work more efficient. Tier 1 suppliers and original equipment manufacturers (OEMs) will need to reorganize their research and development teams and supplier relationships to develop these new connected and intelligent vehicles more efficiently. Enabling engineers to develop products faster and with fewer resources has become a key priority.

Read More

Dojo—a space for immersive learning—is no longer a term associated only with martial arts. It has been appropriated by other disciplines, including software. Fittingly, Tesla’s new supercomputer, named Dojo, is touted to be the world’s most powerful AI training platform and promises to be a game-changer in the high-stakes autonomous vehicle race. Unveiled at Tesla’s AI day event in August last year, the company is set to share more about the progress made over the course of the past 12 months at this year’s AI day event scheduled for September 30.

Read More

The trade fair comes at a time of enormous change for the automotive market. With the ongoing Ukraine-Russia conflict, global trade tensions, and the semiconductor crisis, market participants have to engage with innovative disruption in the form of connectivity, autonomous, sharing/servicization, and electrification (C.A.S.E.) trends. Meanwhile, intensifying concerns over climate change and rampant resource consumption have been compelling stakeholders to embed sustainability paradigms across the ecosystem. Against this background, technology is proving a powerful game-changer, with digitalization transforming industry dynamics.

Read More

The CHIPS Act is set to support the US semiconductor industry with $280 billion in government assistance and public subsidies. Of this, $52 billion worth of subsidies and additional tax credits will be allocated to US companies for domestic chip manufacturing, a 25% tax credit will be extended to investments in semiconductor manufacturing until 2026, and a significant $200 billion will be channeled toward research, development, and innovation in semiconductors and allied technologies.

Read More

In 2021, the automotive industry witnessed a flood of Special Purpose Acquisition Company (SPAC) deals totaling more than $16 billion, highlighting how SPAC mergers have become the go-to strategy for tech companies and start-ups looking to fast-track their way to a public offering. For such companies, the SPAC route presents multiple benefits: the ability to raise capital in a less risk-intensive and more cost-effective manner than if they took the traditional initial public offering (IPO) approach, fewer due diligence requirements, and faster commercialization and growth if the acquirer is a well-established SPAC sponsor.

Like many other industries, circular economy concepts are gaining increasing traction in the mobility industry. In a sign that the industry is thinking collaboratively about sustainable practices, a national rail operator and a leading automaker have joined hands in a unique partnership to promote battery second life applications. Deutsche Bahn (DB), Germany’s national rail service operator, will be teaming up with leading automaker Kia to extend the useful life of lithium-ion batteries in Kia’s Soul electric vehicles (EVs) by repurposing them for second life use in battery energy storage solutions.

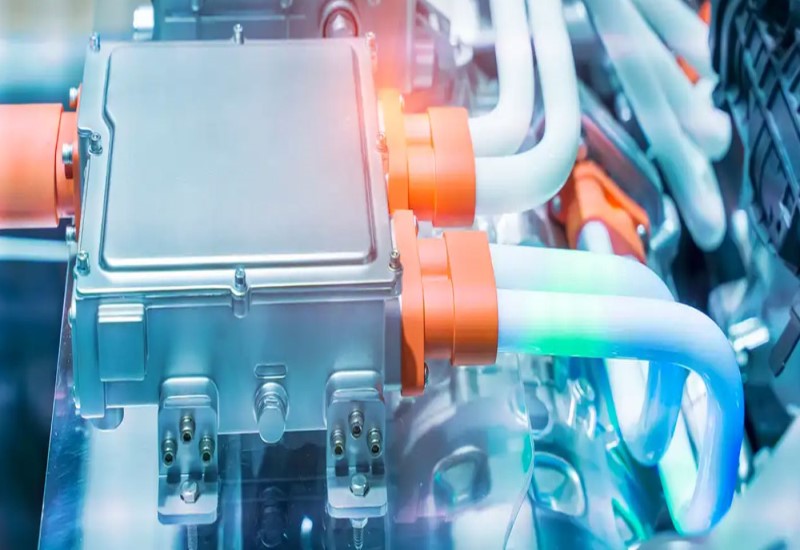

The increasing adoption of electric vehicles (EVs) has pushed the need for efficient battery solutions, augmented safety, and an extended life span. Frost & Sullivan’s recent analysis finds that many research institutions, battery suppliers, and key original equipment manufacturers (OEMs) are collaborating to develop future battery chemistries with effective material performance, reduced production costs, and enhanced safety.

Read more